Introducing Fabrum

Hydrogen is widely regarded as a key pillar in a future clean energy ecosystem. Green hydrogen, produced by the electrolysis of water, has a key role to play in decarbonizing numerous industries. One of the key challenges in its adoption is waste when transferring liquid hydrogen from one vessel to another, or during its storage.

Fabrum’s newest pieces of technology will enable customers in a broad range of sectors to transition to zero-loss liquid hydrogen handling and storage. The result is a potential 25% cost reduction per kg, helping to drive demand for green hydrogen and associated technologies, along with a reduction in emissions.

Who are Fabrum

Christchurch based Fabrum was formed in 2004 by two Canterbury University engineering students, Hugh Reynolds and Christopher Boyle.

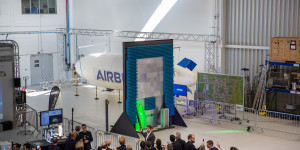

For twenty years they’ve been developing small to medium liquefaction systems and composite cryogenic vessels used globally in heavy transport, mining and aviation industries. They operate around the globe with 80% of their product made in New Zealand and exported globally.

Their two decades of hard work has resulted in an impressive library of patents and trade secrets, along with a product catalogue that includes cryocoolers, refuelling technologies, liquefiers and storage systems, for hydrogen, nitrogen, oxygen and LNG.

They have a clear, bold mission: to create technology that enables humanity to do more, using less, and for longer.

Benefits to the innovation ecosystem

The main impact of Fabrum’s project is a reduction of the cost of green hydrogen. A reduction in cost not only increases demand, but also creates new opportunities for other businesses to create associated technologies.

Fabrum are planning to establish a hydrogen test facility – the first in Aotearoa. The facility will be highly sought after by academia, as well as a broad range of businesses from across the globe with a vested interest in hydrogen systems. Additionally, they’re looking to establish new high volume manufacturing capability.

Alongside the new facilities, the team will be forming a centre of excellence, which will act as a hub for collaboration and knowledge sharing, directly enhancing the capabilities of local engineering and manufacturing firms.

As the project contributes to the setting of regulatory benchmarks, the team will be stepping up their efforts to share knowledge with policy makers, as well as other private firms and research institutions.

What the panel had to say about Fabrum:

Fabrum is taking off on a new trajectory. The team identified opportunities early on and bravely took strategic decisions to chase them.

Their honesty and openness were welcomed by everyone on the panel and will no doubt play an important role as they move forward as an organisation.

The team are already heavily involved with their wider industry and policy makers, and will undoubtably continue to blaze a trail for the sector for years to come.

How Fabrum will be investing their grant

Ārohia funding will aid Fabrum in setting up their new facilities, as well as implementing cutting-edge data-led manufacturing technologies. The team will grow in size thanks to recruitment of new key roles and their supply chain will be optimised.

All of this will ensure Fabrum can rapidly scale up production from 4 to 50 units per annum, achieving a greater speed to market, and securing first-mover advantage.

“Fabrum has a clear mission to precision engineer better outcomes through technological excellence, to enable the world to tread lightly. It is our honour, to be a Ārohia Trailblazer Grant Recipient and to receive immense support to bring a hydrogen testing and excellence centre to Christchurch’s innovation ecosystem. This grant will also enable Fabrum’s patented boil off gas management system to enter the market providing solutions to allow a clean energy future.”

Christopher Boyle, Fabrum, Executive Chairman

Fabrum

Founded: 2004

Sector/industry: Hi-tech engineering

Think you could be a Trailblazer?