Opportunity

Manufacturers need faster and more convenient ways to prototype products to increase innovation and speed to market.

Solution

Foundry Lab lets manufacturers cast on-demand, production quality metal parts at a fraction of the cost and time of a traditional foundry.

![]()

David Moodie's "backyard project" became the basis of the startup Foundry Lab after the Wellington-based industrial designer received a visit from WNT Ventures.

“WNT’s Laura Faulconer came down to see one of my clients and she had an hour to kill before her flight. She said, what else are you working on?” Moodie recalls.

That backyard project he showed Faulconer was a metal casting system that combines the ease of 3D-printing with the density of metal casting. Moodie wasn’t looking to raise money or go global with his invention.

But the due diligence process the team at WNT Ventures undertook on Moodie’s system revealed the huge cost savings and timesaving it could deliver manufacturers seeking to prototype metal products, allowing them to go from CAD design directly to production in a single day.

Foundry Lab was born in 2018 and quickly joined WNT’s deep tech incubator. The $150,000 injection of capital from WNT and $450,000 repayable grant from Callaghan Innovation allowed Moodie to further develop his own prototype of the Foundry Lab system, while WNT advised him on how to find potential customers in the all-important US market.

“They took a huge risk when they came on. I had cast a few parts but not a full system. They saw the potential for the market even more than I did,” says Moodie.

“They were great listeners and were very fair and measured when I talked through what I had in mind.”

A $35,000 pre-incubation grant allowed WNT to go deep on exploring the viability and market potential of Moodie’s technology.

“We are an active investor,” says WNT Ventures Managing Partner Carl Jones, who has been on the Foundry Lab board since 2018.

"Finding a trusted partner really early on is critical to a lot of these companies and the founders, especially when they are a little bit less experienced. That’s the value we add."

Critical too was the technical expertise Foundry Lab was able to draw on within Callaghan Innovation’s scientific ranks.

"Callaghan just happened to have a powder ceramicist. We were able to develop something that was first in the world and is world-leading because we had access to people who really knew what they were doing," he says.

Interns funded through Callaghan Innovation-funded student grants have gone on to become employees at Foundry Lab, which raised money from Founders Fund & Promus Ventures in 2020, followed by a series A round in 2021 with funding from Blackbird, GD1 and Icehouse Ventures. Foundry Lab is now preparing its Series B funding round and has opened a demo facility in California.

"We’ve gone full circle at Foundry Lab after getting access to capital and machinery from Callaghan. We’ve now developed our own sophisticated machinery, employed 31 people and are about to raise more capital. It shows the economic impact of that early support,” says Moodie.

Having access to that extra capital was the difference between sinking and swimming... We wouldn't have got anywhere without it.

- Daivd Moodie Foundry Lab

Over the last decade, we've built deeper technical and funding pathways offshore, and a deeper pool of founders who have been there and done it, and can recycle themselves back into helping each other.

- Carl Jones WNT Ventures

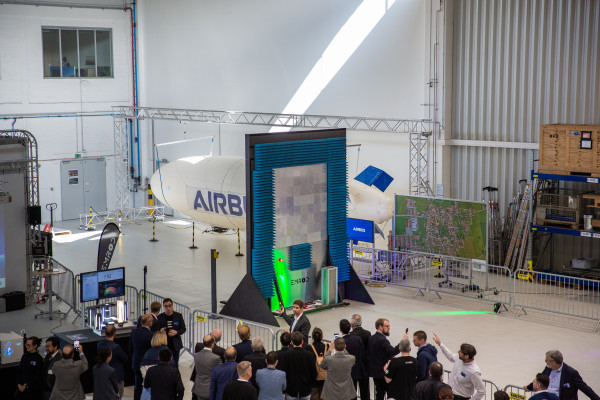

![]()

$14 million raised to date

Read more from the Unleashing innovation: A decade of Deep Tech report.