Who knew so many raw materials and precious metals lay within our electronic waste. Well, Mint Innovation did. And with Callaghan Innovation’s help they’ve developed technology that extracts gold from it.

At a glance

- Helping to tackle the large amount of electronic waste (e-waste) in the world, and tap into the raw materials it all possesses, Mint Innovation has developed technology that extracts gold from e-waste.

- Callaghan Innovation has supported their commercialisation journey, with grants such as the R&D Experience and Career Grants helping them source talent from universities that accelerated their R&D.

- Mint Innovation is set to take the award-winning technology to different offshore markets, as well as set up two commercial facilities in New Zealand.

Finding a goldmine within electronic waste

Most of us have an old phone or laptop lying around. Well, we could be sitting on a gold mine.

The amount of global electronic waste (e-waste) is huge. In fact, in 2019 the world generated 53.6 million tonnes of e-waste (according to the 2020 Global E-Waste Monitor). However, all that waste contains many rare and valuable raw materials, even gold, that in 2019 was valued at approximately US$57 billion.

The problem is e-waste is not cheap or easy to recycle - only around 17% of it is effectively recycled. That means just US$10 billion of those raw materials is recovered, with the rest left in homes, recycling stockpiles or causing environmental degradation in landfill.

It’s a massive global problem, but one in which a Kiwi cleantech firm Mint Innovation sees rich opportunity.

Mint Innovation has developed innovative technology to recover metals from complex waste streams. In particular, it has developed a process that uses a mix of hydrometallurgy and biometallurgy (the use of liquids and microbes respectively, to separate out metals) to extract pure gold from e-waste.

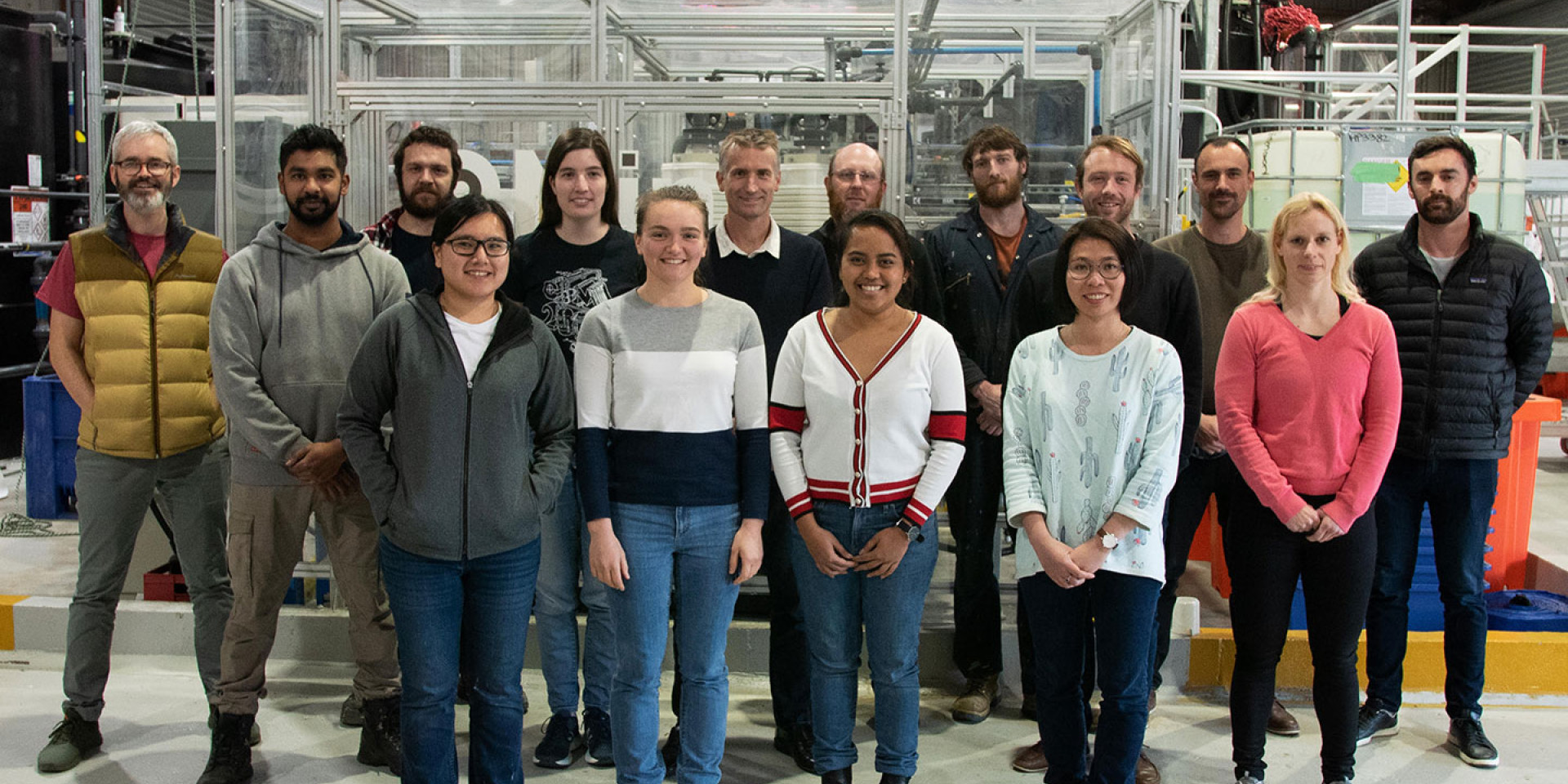

Mint Innovation site

Scaling with support from Callaghan Innovation

Commercialising Mint Innovation’s ‘biorefining’ technology – a low-cost process that uses inexpensive chemicals and naturally sourced microbes – has been the company’s biggest challenge on its innovation journey, says Mint Innovation’s commercial lead Thomas Hansen.

Raising $5.2 million in 2018 certainly helped, letting the company establish its pilot plant in Auckland, which is now processing 1 tonne of e-waste at a time. As has a wealth of support from Callaghan Innovation, including R&D Experience and Career Grants, as well as tapping into our R&D services.

Phil Anderson, a Callaghan Innovation business innovation advisor for the HighTech Products sector, says the company has made particularly good use of R&D Experience Grants. These have allowed the company to employ a number of university students across numerous summers and has meant Mint Innovation could pursue R&D at a faster rate. It’s also led to a number of interns going on to be employed within the business after graduation.

Wasting no time in going global

Mint Innovation is well on their way to success, already recognised as the Most Innovative Deep Tech Solution at the 2020 NZ Hi-Tech Awards.

They’re looking to raise US$10 million in a bid to continue their commercialisation journey, they’re keen to enter both the UK and Australian markets, and they’re hoping to have two commercial facilities up and running.

Hansen also intends to help bring on board partners who can help the company accelerate the adoption of the technology – anyone from downstream collectors of e-waste, such as existing recyclers, to electronics producers. In fact, in the future he sees Mint Innovation’s technology able to be applied to any complex, metal-rich waste stream.

“We want uptake of this technology to be limited only by the ambition of our customers. Ultimately, I see the company as a licensor of this circular economy cleantech – Kiwi innovation enabling the world to better manage its waste.”