Humble Brag #001: This is the first of a series of articles based on conversations with trailblazing New Zealand innovators who have already had massive global impact but are continuing to innovate in new areas. Each instalment of The Humble Brag will explore their unique approaches to innovation, leadership, and shaping our collective future through their respective fields.

Callaghan Innovation CEO Stefan Korn sat down with Richard Taylor, co-founder of Wētā Workshop, to discuss his experiences expanding the company from a service-oriented business into a product and services company through, among other things, seriously impressive ingenuity in robotics and their aspirations towards AI.

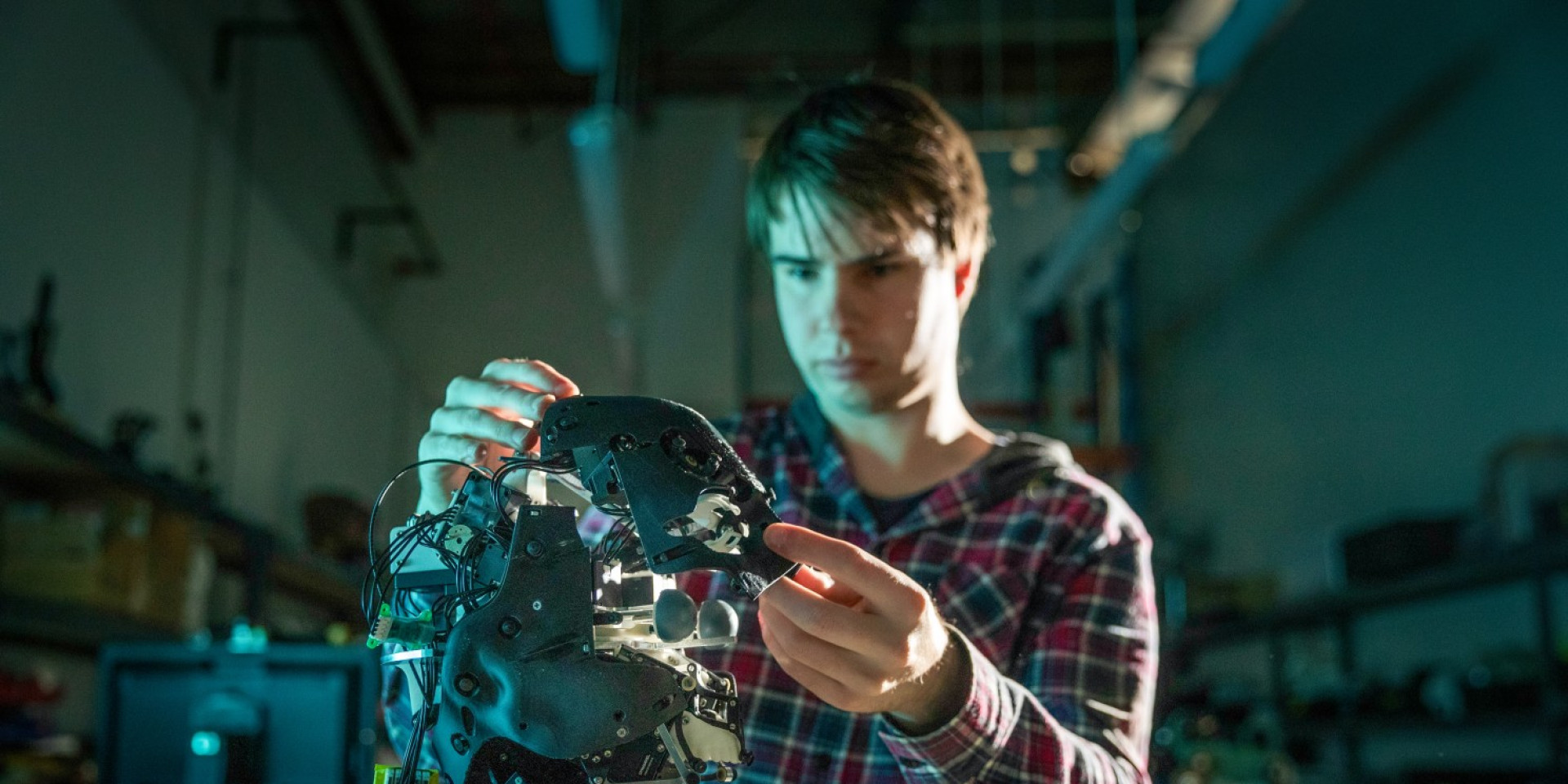

I’m very excited by the challenge of trying to productise and then commercialise something as complex as a humanoid robot. As a New Zealand company mostly known for our service work on film and immersive experiences, it’s a thrilling prospect to try and turn something such as this into a product. So, we are focused on trying to create ‘WētāBot005’ as our first productised robot.

Though Wētā Workshop is renowned the world over for creating magical special effects in films and TV shows, over time, the company has evolved into new territories, following the evolution of new technologies and applying them to their creative endeavours. During this time, Richard and the workshop team experienced the challenges of revenue uncertainty in service companies first-hand, which is what drove them to start the now successful collectables business, for instance. More recently, Richard, business partner Tania and their team decided that the company needed to do something that would challenge them all creatively, technically, and commercially by trying to create a product for a quickly growing part of the creative industries — what’s been called the experience economy. It‘s currently dominated by theme parks, but with the explosion of smaller themed experiences appearing around the world, Richard and his robotics crew are hopeful they can find a space in this exciting and growing market.

The productisation journey hasn’t been straightforward; commercialising an existing technology or expertise into a repeatable and scalable product is challenging, especially when there is little time to conduct extensive testing.

You wouldn’t put a Formula 1 car into a race unless you’ve spent a year racing and refining it on your own track. Luckily, our most recent client, MACK One, who has also been a wonderful collaborator, understands that we’re having to use their live environment as our test track.

Image courtesy of Wētā Workshop and Europa-Park

The WētāBot is already in use in the form of Jeff, the ‘Head of Security Orc’ at Wētā Workshop Unleashed in SkyCity, Auckland, as a technology testing robot at a company in the US, and at the Europa-Park theme park in Germany in collaboration with MACK One—even though the current technical readiness is still below the level Richard knows the team and technology can reach.

Richard explains that the original Callaghan Innovation grant* enabled Wētā Workshop to get to version one of the WētāBot, which was perhaps 60% of a finished product. The first build was crucial as it allowed the company to continue developing the technology iteratively and get to 70%, 75%, and 80% — with the hope of finally getting to 90% with their latest version of the WētāBot 005.

So why not aim for 100% to launch the product? Richard explains:

It may take us another ten years and the potential of a great deal more money to get from 90 - 100%. What we need to do is try and get our first product into market at a level we are confident will fulfil our clients’ expectations and with the hope that we can start earning revenue. This way we can choose to re-invest the funds back into getting to 100%.

Richard’s approach lines up with one of the most important commercialisation insights we see at Callaghan Innovation based on our work with thousands of New Zealand innovators: Don’t wait to launch your product until it is perfect. Wanting to launch a 100%-level product is probably the most common mistake we see with New Zealand companies. As the old saying goes, perfect is the enemy of good, especially when it comes to commercialisation and productisation. However, it is also important (as demonstrated by the team at Wētā Workshop) that after the initial launch, the product must be improved iteratively and at pace.

To us, the most aspirational team building human-like robots are the Disney Imagineers. They have been building world-leading humanoid robots for many decades, working at the aerospace level of design and build methodology. Understandably, they are working to fairly large development budgets and building off tried and true processes while innovating from this base. Although we have been building animatronics for the film and TV industry for most of our career – we are a relatively new team to this exciting field of humanoid robotics for long-life performance environments.

Therefore, what Richard and the team are trying to think about is how to approach product development in different ways that might provide a point of difference. This difference being where they can achieve the results they are aspiring to, while hitting a price point that could give them accessibility to certain clients. By focusing on innovating new methodologies, trying to develop novel component fabrication, and chasing down credible and cost-effective manufacturing techniques – they hope they can aspire to the likes of Disney (and other amazing companies) in the coming years.

This is a very high bar, and we have a hell of a way to go yet, but we hope that by challenging ourselves with this sort of exciting goal – we will continue to pursue this with enthusiasm and passion.

By leaning into additive (3D) printing, the Wētā Workshop team could build animatronics with durable, remarkably light chassis at a much lower cost than if they’d gone the heavy engineering route. When Richard met up with Chuck Fawcett, one of the world’s leading animatronics engineers, on a recent trip, he confirmed that their instinct to build robots using additive printing was, in his view, possibly the only feasible way to create a fully functional animatronic robot that costs significantly less to manufacture. But there are also other advantages, and certain risks, as Richard explains.

It is our goal to empower our up-and-coming technicians to be able to do a sizeable amount of the pre-assembly of the final WētāBot under the watchful eye of our more experienced engineers.

This will allow our senior team to continue work on the upfront design, prototyping, and software engineering.

This approach gives these young folk a fantastic opportunity to cut their teeth on something truly special, while also freeing up our senior engineering team to carry on with the further iterative work, pushing to get us from 90 to 100%.

The move to building products rather than bespoke one-offs has also brought one challenge the team was surprised by.

The fragility of some commercially purchased components has really surprised us. Some components that you would expect to be infallible have proved to be less so, which has been really disheartening. So, we have been communicating with other roboticists around the world - to compare notes about the quality of specific components so that we could be more effective collectively, and in turn, hive mind our knowledge base for everyone’s benefit.

Richard’s experience lines up with what we are hearing from other cutting-edge tech companies in New Zealand – there are always unexpected obstacles that come your way in technology commercialisation. Unexpectedly faulty components are one of the obstacles, and Richard's team are trying to combat this issue by rigorously testing any brand new, third-party components – essentially doing another quality control on top of the manufacturer’s checks. Secondly, Richard is insisting that all WētāBot componentry, including wiring, is coded with unique tracking codes to ensure quality and traceability. Richard talks enthusiastically about the team’s ethos to include tracking codes even on minute components (and the beautiful nod to Bladerunner’s microscopic serial number on the scales of an artificial snake was not lost on us). Overall, these initiatives and commitments are all part of Richard’s way to instil an aero-space mentality for high-level precision and reliability within the practical constraints of a Kiwi workshop.

I can't provide you with a NASA lab, but I can provide you with the mindset as if you were in the NASA lab. If you keep whittling with a knife, you may never evolve … your mindset is limited to whittling. But when you give a whittler access to a 3D printer, a water jet cutter, or a CNC mill, and they bring the same level of creative dexterity and Kiwi can-do attitude to the use of this technology as they did to their whittling, it's a game changer – and those are the leaps we've been trying to make for the past 36 years.

This mindset of pushing boundaries and exposing highly talented artists and engineers to new technologies is a constant thread that links most things that happen at Wētā Workshop. As such, it is no surprise to hear from Richard about the team’s latest exploration of AI for their animatronic robot Jeff – their cheeky “Head of Security Orc” at Wētā Workshop Unleashed tourist attraction in Auckland. The company’s efforts to create a WētāBot over the last few years have focused on Jeff’s ability to move like a human and perform human-like facial expressions. Jeff has been performing every fifteen minutes, ten hours a day, almost every day of the year, for the past four years. The workshop team are now focused on trying to add an AI personality component to this WētāBot so Jeff can interact with people in a more human way.

The art of innovation is to throw yourself at failure……. and miss, right?

With a subtle reference to Douglas Adam’s ‘Hitchhikers Guide’, Richard sums up Wētā Workshop’s approach to innovation and takes us into the personality of Jeff, who is starting to become self-aware enough to be able to make a “dad joke” or two. So, when Jeff 2.0 got asked recently what he thought of Richard - he responded by saying, “Richard is a bit ‘orcward’ – see what I did there, I’m an Orc and the boss is orcward?” It's early days for the team at Wētā Workshop with AI, but the opportunities for robots that can create deep connections with humans through their human-like movements and personalities are potentially world-changing for the team working in the robotics department:

We want to dive deeply into AI capabilities for our robots, to explore how we can create – say, an educational model that a child may be more comfortable talking to, or a robot that is empathetic enough that an elderly person suffering from loneliness, would find solace in their personality.

And once you’re thinking about that, it opens the door to a branch of robotics that could use AI in animatronics to create companion robots,

that emote through their faces, voice and bodies to help quell loneliness and emotional disconnection in those in our society that really need loving companionship and attention from another being,

which Richard sees as one of the biggest tragedies in the world these days. With Wētā Workshop’s long history of breathing life into characters that people can connect to, this is absolutely within Wētā Workshop’s DNA to accomplish.

Image courtesy of Wētā Workshop and Europa-Park

A conversation that started with key insights on the productisation of deep service and project expertise and ended up discussing the future of humanoid robots is exactly the sort of inspirational, insightful journey I was hoping for with our Humble Brag series.

We'd like to finish with one of our favourite quotes from Richard during the interview:

The adoption of technology can not only help to print money for people but also evolves the mindset of the people using it.

Thank you very much for sharing your incredible insights and mindset with us, Richard. At Callaghan Innovation, we hope to continue assisting Wētā Workshop in taking its WētāBot to 100% and realising many other product ideas, too!

Wētā Workshop received a Callaghan Innovation match-funding project grant in 2021 (with a grant value of $82k) to work on the WētāBot. This type of grant is no longer part of the Government’s suite of innovation and R&D grants, but several other grants and services are available from Callaghan Innovation to help companies with their R&D journey.