Christchurch firm Fabrum Solutions has turned Callaghan Innovation-invented cryocooler technology into a burgeoning export industry. Even NASA is using it.

At a glance

- Older cryocoolers - refrigerators that operate at extremely low temperatures have been unreliable and costly.

- Callaghan Innovation (and previously IRL) developed a cryocooler that solved the problem, with Fabrum Solutions taking on commercialising the technology in 2014, with further support from us.

- Fabrum Solutions has taken the technology a step further, finding a way to liquefy air on-demand. The company is on track to develop a multi-million-dollar export market, with the likes of NASA already a customer.

A pretty cool technology, and technology transfer

It’s a far cry from Hollywood movies freezing people to sleep for years on end. But Fabrum Solutions took on the challenge of commercialising a cryocooler, set to solve a multitude of industrial problems.

Essentially a fancy refrigerator, a cryocooler turns any atmospheric or natural gas into a liquid at very low, or cryogenic, temperatures - from -170º C to -250º C. However, old-style cryocoolers were unreliable; they required regular servicing, and usually failed completely after a few years given that over time oil vapour from the moving parts would get into the cooler’s helium working gas.

With this in mind, former Crown Research Institute Industrial Research Limited (IRL) - now part of Callaghan Innovation - developed a cryocooler with a compressor that is completely sealed. This means the contaminants stay out of the helium working space and the cryocooler can keep running indefinitely.

Then in 2014, Fabrum Solutions took on the task of commercialising the technology, its first focus on manufacturing cryocoolers that could produce on-site, on-demand liquid nitrogen. From there, they’ve gone on to help develop the first liquid air plant.

Running side by side with Callaghan Innovation

Fabrum Solutions puts around 30 per cent of its turnover back into R&D and has partnered with Callaghan Innovation at each step of its journey, Co-founder Christopher Boyle says.

Not only did some of the original staff move over to the company as part of the technology transfer, Callaghan Innovation has continued to support Fabrum with a number of R&D grants and funding.

Alan Caughley, the scientist behind the original breakthrough, these days Team Leader Mechanical Engineering at Callaghan Innovation, worked with Fabrum throughout the commercialisation project.

“We were running really hard as a combined team for several years, with our engineering team helping them put the early prototypes into the field,” Caughley says.

“This has been an amazingly successful technology transfer. Creating a mid-range refrigerator that produces a useful amount of liquid has been something of a holy grail.”

Endless applications, huge market potential

The market for Fabrum is huge, with the Kiwi invention aiming to take a portion of the annual $2.4 billion international market for cryocoolers, in the process potentially creating a new $100 million export industry for New Zealand.

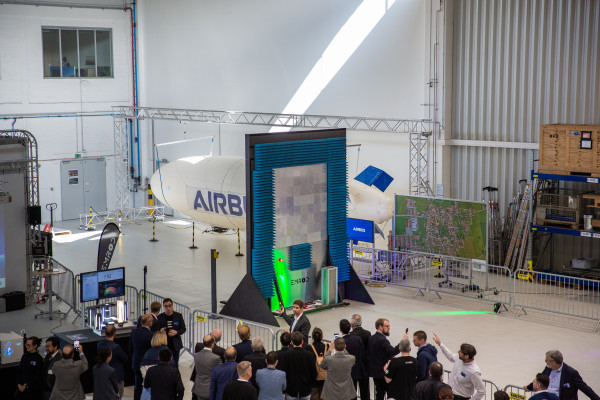

To help achieve this, Fabrum formed a joint venture with French cryogenic engineering company Absolut System, called AFCryo, and has capacity to manufacture around 200 units a year at its purpose-built Christchurch facility.

There are endless applications for the cryocoolers, everything from the space race to fertility treatment. In fact, NASA is already using one of its cryocoolers to freeze carbon dioxide as part of the Mars Lander project.

“There are a whole range of uses we never appreciated when we started on this journey,” Boyle says.

Some of the applications Fabrum has never even thought of. For example, the likes of firefighters and military personnel can carry a backpack of liquid air allowing them to work in hazardous situations for longer, given the evaporation of the liquid provides a cooling effect in the incredibly hot suits.

As well, cryocoolers also allow for on-demand liquid oxygen wherever it’s required, from air ambulances to remote military bases. They are also used for producing liquid nitrogen to preserve semen as part of animal artificial insemination programmes and human fertility treatment.

It also boasts environmental credentials, with the cryocoolers able to re-liquify the methane that is vented off LNG when it is transported, especially helpful as Europe moves towards zero emissions of methane.